by Yoichi Hariguchi

Convesely, if the blade angle increases, the required torque increases. Then the engine and the propeller will tend to slow down.

Thus, we can control the RPM by varying the blade angle or pitch of the propeller.

Oil pressure acting on the piston in the propeller produces a force that is opposed by the natural centrifugal twisting moment of the blades and a spring. This moves the piston back. Motion of the piston is transmitted to the blades through the actuating links and pins, moving the blades toward high pitch.

When the opposing forces are equal, oil flow to the propeller stops and the piston will also stop. The piston will remain in this position holding the pitch of the blades constant until oil flow to or from the propeller is established by the governor. Pitch is decreased by allowing oil to flow out of the propeller to be returned to the engine sump. When the governor initiates this procedure, hydraulic pressure is decreased and the piston moves forward, which moves the blades toward low pitch. The piston will continue to move forward until the opposing forces are again equal.

When the throttle is fully open, the pressure downstream of the throttle valve approaches that of the atmosphere. In other words, the air is forced into the induction system at the maximum pressure the atmosphere is capable of pushing.

Consequently, manifold pressure gives an approximate measure of engine power.

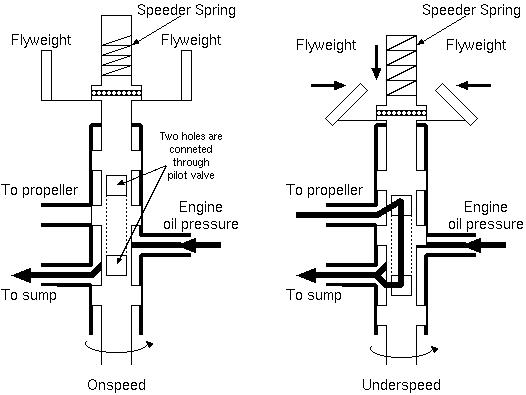

The propeller governor uses the same principle of Flyball Governor invented by James Watt in the 18th century! A look at the governor and total system will help to explain how it works.

The governor mounts on and is geared to the engine. This drives

governor gear pump and the flyweight. The booster gear pump

boosts engine oil pressure to provide quick and positive

response by the propeller. The rotational speed of the flyweight

varies directly with engine speed and controls the position of

the pilot valve. Depending on its position, the pilot valve

with direct oil flow to the propeller allow oil to flow back

from the propeller, or forward to the propeller.

How Does the Governor Control RPM?

Please refer to the pictures in

the "What Is Governor"

section as well as the figures in this section for

understanding how the governor controls engine RPM.

The flyweights (5) are installed with their lower legs projecting under a bearing on the pilot valve (10). When the pitch of the propeller blades is too low to absorb engine power, the engine RPM increases and it becomes higher than the propeller control setting. This is called overspeed condition. In the overspeed condition, the flyweights are open since the centrifugal force against the flyweights is high. Hence, the upward force by the flyweight becomes greater than the downward force by the speeder spring. As the result, the pilot valve is forced up and oil from the booster pump flows into the propeller.

This increases the pitch of the blades. Engine speed then slows down to maintain the original RPM setting.

On the contrary, in the underspeed condition (the engine RPM is lower than the propeller control setting), the flyweights are closed since the centrifugal force against the flyweights is small. Hence, the upward force by the flyweight becomes less than the downward force by the speeder spring (3). As the result, the pilot valve is forced down and the oil flows from the propeller.

This reduces the pitch of the blades. Engine speed then increases to maintain the former RPM setting.